Neil

Well-known member

- Messages

- 3,733

Lovely set up there #jimmyboots Where did you get the sack barrow from

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: this_feature_currently_requires_accessing_site_using_safari

Haha, I did mate. I have made much cheaper ones but this is built to last.Looks very professional Jimmy. I bet you got a lot of satisfaction building that.

Yes you cant beat pneumatic tyres. This was my first Trolley a few years ago, which I later swapped the tyresI haven't built one myself. I needed something really compact as I use a car, so I use a Freedom Trolley. But I do enjoy refining my equipment to get the best out of it and to reduce the stress on me. Best thing I've done recently is to fit pneumatic tyres (instead of solid ones), a backpack pump in place of the Sureflo (it bolted straight on with no need to drill more holes), and reduced the battery from a 26ah to a 7ah one. Getting it in and out of my car is a breeze now, it's so light.It runs all day on residential work no problem. The battery is easily swapped out in case it needs changing. And I keep a spare tyre and battery in the car. The difference in weight is also noticeable when carrying a full barrel of water. All in all I'm well happy. I reckon the guys at Pure Freedom should sell a light version alongside their standard one.

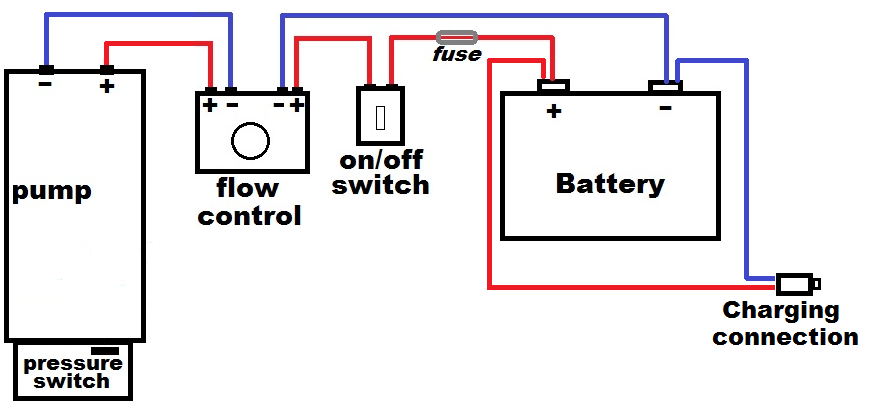

Thanks for quick reply, appreciated! No LED on the switch. I have two switches, one for switching everything on(not attempted to connect this up yet) and the one that I tried to wire up today, this one was to enable me to switch the voltmeter off when using the trolley. Do I need another in line fuse on this switch? Im guessing I overloaded the switch by not having a fuse to it??Hi steve if its just a on off switch WITHOUT LED just goes like this on the+..battery...fuse, i use a red 10amp...in-switch...out switch...flow controller but mix the volt meter wire with the + on the flow controller.

-..battery...straight to the - flow controller with the - part of the volt meter mixed in... BUT if you have a LED splice into the negative and connect to the copper part of the switch.

hook up the pump as normal from the flow controller

i hope this helps matey

Cheers again. Like I say, electrics are like a foreign language to me! Will have another go tomorrow. Bought a second in line fuse from Maplin's. After today's sparks and smoke, I prefer the protection.fuse is always best but its personal preference really mate. easy to use 2 spade connectors on a fat not micro car fuse.ok if its JUST for the volt meter

+ goes to the fuse (if your using one)switch and out of switch to the volt meter

- goes straight to the volt meter

What do you mean by "one side" of the circuit? Are you saying use both switches on the "negative" side? It confuses me about the switch too. Is there a + and - side to them? Cannot see any marks etc.The on off switch can go anywhere as long as it is only on 1 side of the circuitPick a wire..i usually use the negative going back to the battery

Cut it and connect 1 wire of the switch to 1 of the ends you made by cutting and connect the other 1 from the switch to the other end you created

Essentially you are making the cut wire 1 piece again

Can't really go wrong with that

Ah, eureka! Realised what I did wrong on the switch.. no wonder there was smoke etc, yikes!What do you mean by "one side" of the circuit? Are you saying use both switches on the "negative" side? It confuses me about the switch too. Is there a + and - side to them? Cannot see any marks etc.

Earlier today I put the + AND - direct from the battery to the switch and voltmeter. I have just wired the other "main" switch following instructions here and the flow meter is working perfectly without sparks lol. I will post pics when I get it all sorted......What did you do?By the negative i mean the cable that goes back to the terminal on the battery that says -

You are essentially breaking the wire and putting the switch in the gap you have made

Then when you flip the switch it either completes or breaks the circuit

With led etc it is more complicated but essentially it is that simple

If you have any problems take a pic and pm it to me as i was taught by my dad who was an auto electrician and taught me how to read wiring diagrams etc