Luke Barnard

Well-known member

- Messages

- 195

- Location

- Yggggv

I've just received a 500L upright tank from Wydale to replace my 350L flat tank and I'm planning to fabricate a frame similar to the Pure Freedom version and bolt it into the chassis.

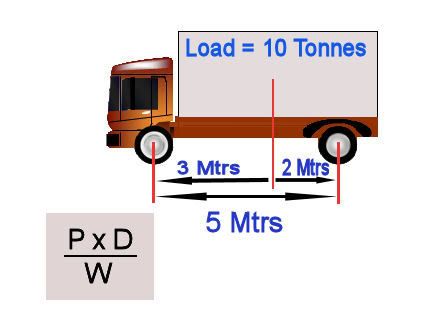

The van is a 2008 Nissan Primastar short wheel base and my question is how far from the bulkhead to mount the tank in order to get the weight distribution rite?

If anybody's got one of these is a Primastar, vivaro or Traffic I'd really appreciate if you could measure the gap between the bulkhead and front of tank and give me a shout.

Cheers.....

The van is a 2008 Nissan Primastar short wheel base and my question is how far from the bulkhead to mount the tank in order to get the weight distribution rite?

If anybody's got one of these is a Primastar, vivaro or Traffic I'd really appreciate if you could measure the gap between the bulkhead and front of tank and give me a shout.

Cheers.....