David Taylor

Well-known member

- Messages

- 603

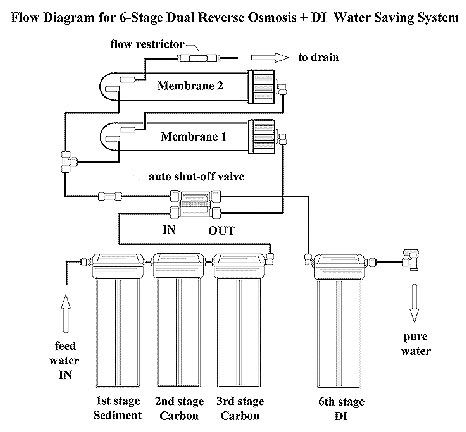

Hi can any one help me? I have a single 4040 ro set up, I want to add a second membrane to speed up production but i`m unsure of the plumbing and can find any diagrams online to help.

If any one has a dual set up i`d be grateful of some advice.

thanks

Dave.

If any one has a dual set up i`d be grateful of some advice.

thanks

Dave.