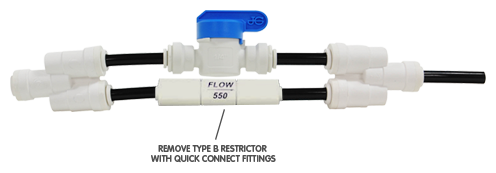

On my old 450GPD I had a combo flush valve and in line restrictor. Here's an example;I think I get it. So are you saying the flow restrictor is what is making my ratio 70/30 with the tap fully open? In that case am I correct in thinking it’s fine to leave the tap fully open on this system?

If so I’m still at a loss to understand why my production has dropped by 10%. I’m gonna give it a super long flush tonight regardless. I don’t think my membranes can be knackered though because my rejection rate is still pushing 99%?

https://www.ro-man.com/?product=flush-kit

The on off valve was in the loop. You opened the valve fully to flush. When you closed the valve the water was directed through the restrictor valve. Inside the valve it had a small nozzle which was a preset size which only let through the required amount of water.

There are other valves that have a small hole in the ball which allows a small amount of water threw even when fully closed and then there are valves that completely shut the water off.

When Purefreedom sell a 4040 they drill a small hole through the paddle of the gate valve. The hole is the right size to give the ratio they want.

When I set up my 4040 I also drilled a small hole through the paddle. It was a safety feature in case my son or son in law decided to mess around with it. ATM I still have to adjust the gate valve to get the lowest pure tds by opening the valve.

Gardiner's used to sell John Guest taps. One would completely shut and the other wouldn't.