Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: this_feature_currently_requires_accessing_site_using_safari

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hose Less Pole Connecter

- Thread starter Chris Dall

- Start date

Help Support WCF:

I used your idea of a plastic tube to guide the hose to the bottom of my barrels too @jimmyboots

A bit different as it is permanently attached to the lid but i can poke the hose right to the bottom

View attachment 6193

A bit different as it is permanently attached to the lid but i can poke the hose right to the bottom

View attachment 6193

W

WWC

These ideas are good, but a question for anone who has had there' on for some time, doesn't the metal female fitting wear on the inside of the poles? Or if you have fitted a hose clip to your female restus, dose that scarpe the inside of the CF pole? I guess you could put a bit of tape around the O Clip, but not the grip on the rectus fitting itself.

The bought femal rectus fittings have a plastic sleeve over them protecting the poles, but a DIY one doesn't.

I'm all for DIY, but saving a few pounds by making this yourself but weakening an expensive CF pole doesn't seem good value. So, thus I ask anyone who had used this DIY system for long enough to cause damage - if it is going to.

The bought femal rectus fittings have a plastic sleeve over them protecting the poles, but a DIY one doesn't.

I'm all for DIY, but saving a few pounds by making this yourself but weakening an expensive CF pole doesn't seem good value. So, thus I ask anyone who had used this DIY system for long enough to cause damage - if it is going to.

mufcglen

Well-known member

- Messages

- 601

- Location

- Manchester

hi wwc not at all, if it was scraping the inside of the poles they'd be stiff extending or closing and im sure youd hear it, the way ive made mine is the female fits onto the male and theres no play for it to catch the inside wall of the pole sections, remember the sections are wider then the actual female rectus so you'll be fine!!

and the plastic sleeve or casing the female rectus fits in is even wider so the rectus can fit inside so thats how much room you have inside the pole!

and the plastic sleeve or casing the female rectus fits in is even wider so the rectus can fit inside so thats how much room you have inside the pole!

These ideas are good, but a question for anone who has had there' on for some time, doesn't the metal female fitting wear on the inside of the poles? Or if you have fitted a hose clip to your female restus, dose that scarpe the inside of the CF pole? I guess you could put a bit of tape around the O Clip, but not the grip on the rectus fitting itself.

The bought femal rectus fittings have a plastic sleeve over them protecting the poles, but a DIY one doesn't.

I'm all for DIY, but saving a few pounds by making this yourself but weakening an expensive CF pole doesn't seem good value. So, thus I ask anyone who had used this DIY system for long enough to cause damage - if it is going to.

stop over thinking things trust me your pole will wear out befoure the metal going up the inside does any damage , my slx25 is used 7days aweek flat out Its never cleaned its never been apart and I just throw it around ,its 18 mounths long and still going strong with the metal going up inside

why do that ? just put a male and a female snap ends on job done , both go inside the pole and both stronger and quicker to change then that plastic thing you use , and quicker to change poles all our poles are fitted with male snap ends so any pole will fit any of our vansView attachment 8930

Lol I join them like this picture with jubilee clamps, one of the advantages of doing it like this is you got the rectus tooked up inside the pole and not getting dragged about on the floor!!

W

WWC

If I treated my poles like that, they wouldn't last 18 months! I guess it may have something to do with our different working environments. My poles need cleaned and treated nicely. They get enough abuse with the debris dragged inside them from the properties I work on. I guess I'm around more mud, dust, stones etc.stop over thinking things trust me your pole will wear out befoure the metal going up the inside does any damage , my slx25 is used 7days aweek flat out Its never cleaned its never been apart and I just throw it around ,its 18 mounths long and still going strong with the metal going up inside

jimmyboots

Well-known member

- Messages

- 688

- Location

- Stoke on Trent

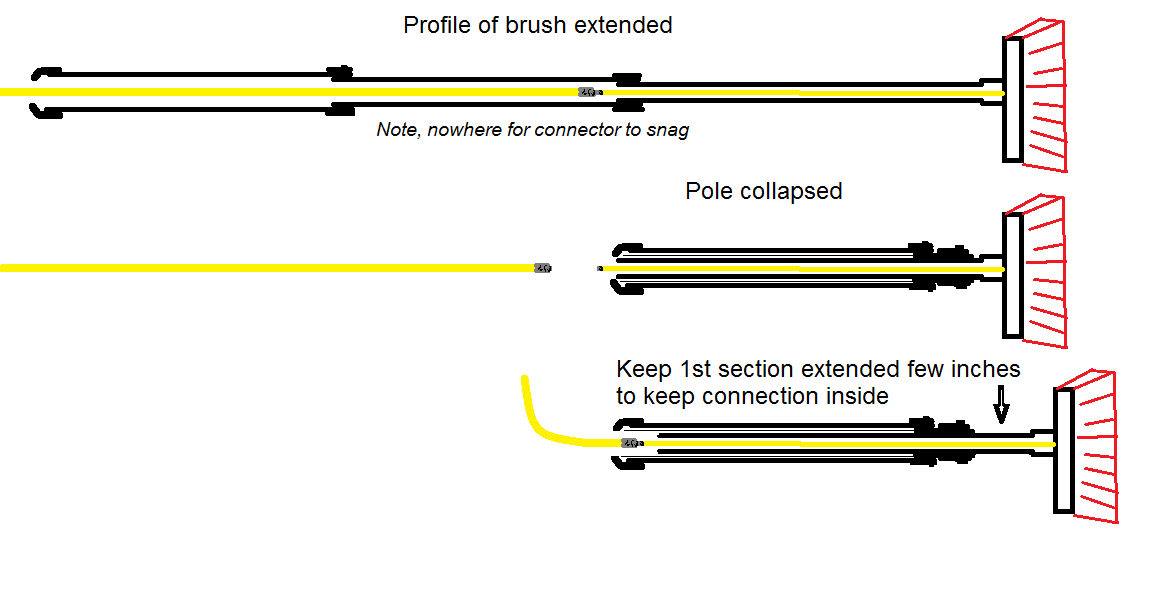

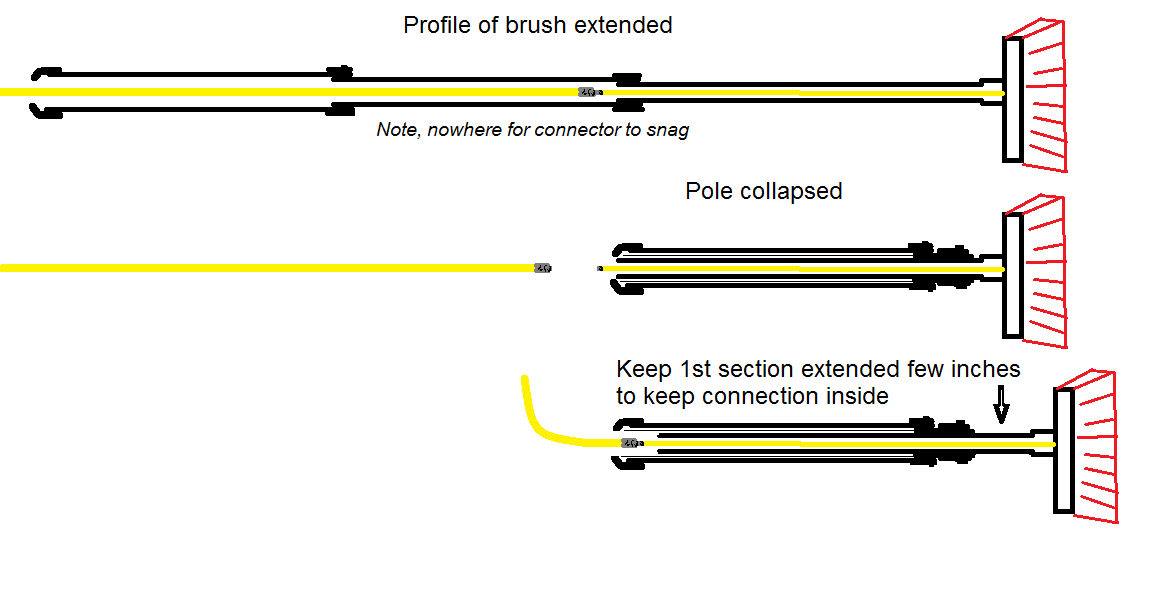

@WWC . The rectus fitting or JG fitting (whatever is used) doesnt slide up and down the pole rubbing on the sides. The pole extends over the hose. The fitting is Stationary in the pole. I know when you think of it working you imagine the fitting shooting up and down the pole but it doesnt.

Heres a diagram

Heres a diagram

mufcglen

Well-known member

- Messages

- 601

- Location

- Manchester

I am using male and female rectus pal?why do that ? just put a male and a female snap ends on job done , both go inside the pole and both stronger and quicker to change then that plastic thing you use , and quicker to change poles all our poles are fitted with male snap ends so any pole will fit any of our vans

I have the male rectus fitted in the end of my pole as per the guide I posted further up then have a female rectus in the end of the pole hose thsts attached to the reel hose, when I disconnect from the pole the female rectus stops the flow of water and I can change to either pole I need!!!!!!

W

WWC

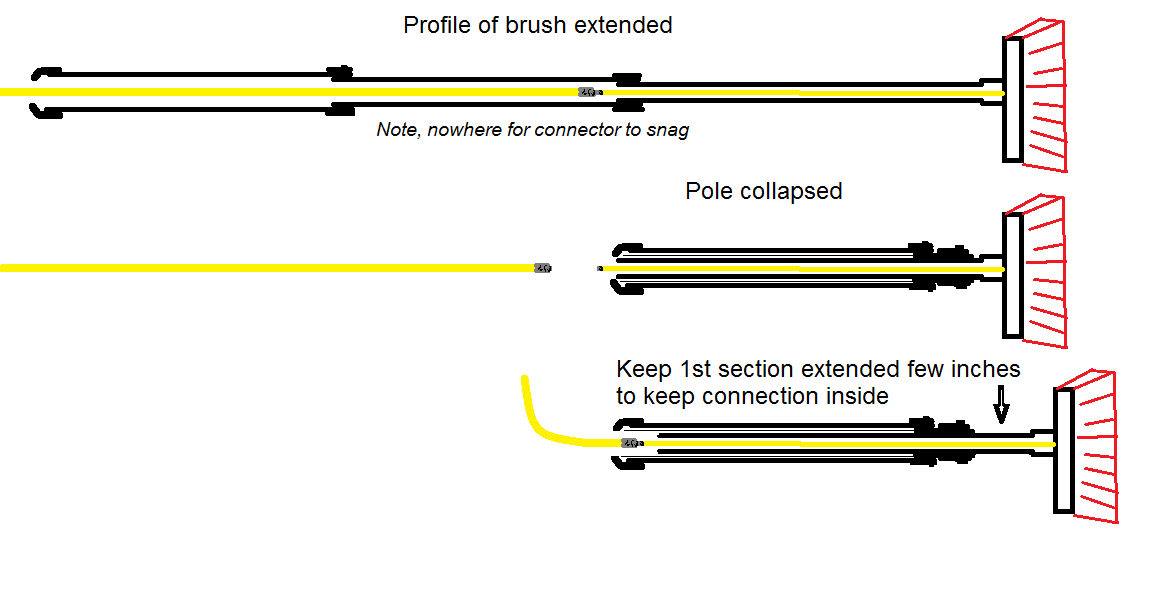

Hi Jimmy, but it does - sort of. The fitting is sitting out the bottom of pole 1. Yes the fitting stays stationary, but pole section 2 slides up and down the fitting every time you extend and collapse the pole. Which you do lots of times during the working day. The fitting has a loose water hose on one end and is bound to pull it down/sideways against the pole wall. Then you slide section 2 up and down on the metal.@WWC . The rectus fitting or JG fitting (whatever is used) doesnt slide up and down the pole rubbing on the sides. The pole extends over the hose. The fitting is Stationary in the pole. I know when you think of it working you imagine the fitting shooting up and down the pole but it doesnt.

Heres a diagram

This movement in the fitting will be even more exaggerated when using hot water, as the pole hose is even more flexible and likely to bend, allowing the metal fitting to rest on section 2.

The fitting may also knock agaist the sides as you brush - like an exterior hose can do against the outside of the pole if not well wrapped around the pole.

Also as I use more than 1 pole in the day, I can't leave it clipped in as you do. So, each time the metal fitting extends past the delicate ends of all the pole sections, it risks chipping the ends - especially section 2, when you extend after a full collapse. Or even if you are working with the pole fully collapsed e.g. the lower windows. The metal fittings will certainly rub against the pole ends then as you move the pole when working. I know that you JimmyBoots, keep your pole slightly extended all day, after you have carefully moved the fitting in past the pole ends - but staff won't. I'm not sure that I would remember either - too much muscle memory already in place.

RED Arrow - ends of pole sections than can get chipped

WHITE Arrow - If the hose pulls the fitting from being exactly plumb with the pole (which it will do) then the metal fitting will contacts the section ends as you are cleaning with the pole collapsed, and as you extend the pole.

Last edited:

Hi Jimmy, but it does - sort of. The fitting is sitting out the bottom of pole 1. Yes the fitting stays stationary, but pole section 2 slides up and down the fitting every time you extend and collapse the pole. Which you do lots of times during the working day. The fitting has a loose water hose on one end and is bound to pull it down/sideways against the pole wall. Then you slide section 2 up and down on the metal.

Also as I use more than 1 pole in the day, I can't leave it clipped in as you do. So, each time the metal fitting extends past the delicate ends of all the pole sections, it risks chipping the ends - especially section 2, when you extend after a full collapse. Or even if you are working with the pole fully collapsed e.g. the lower windows. The metal fittings will certainly rub against the pole ends then as you move the pole when working. I know that you JimmyBoots, keep your pole slightly extended all day, after you have carefully moved the fitting in past the pole ends - but staff won't. I'm not sure that I would remember either - too much muscle memory already in place.

This movement in the fitting will be even more exaggerated when using hot water, as the pole hose is even more flexible and likely to bend, allowing the metal fitting to rest on section 2.

Self-adhesive sponge tape wrapped around the hose so that the hose in-effect the hose becomes a larger diameter than the fitting.....job done :thumbsup:.

Last edited by a moderator:

W

WWC

But the tape would need to be on the extrension reel hose, then it would be a PITA fitting each time and getting it into the hose section. I hate to think how many times a day I attach a pole or fully collapse and extend. Each time you would need to fiddle to get the taped extension hose into section 2.Self-adhesive sponge tape wrapped around the hose so that the hose in-effect the hose becomes a larger diameter than the fitting.....job done :thumbsup:.

I honest;y think that Exceed and WCW have come up with a good solution with their sleeve and how it fits inside section 2 from the start by the adjustment of section 1 - cut or the extension over piece to simulate section 1 being shorter.

W

WWC

Guys, I'm not trying to cause trouble, its just that I see a problem, which may be nothing, or may be an expensive issue. I have played with this concept a bit some time ago myself, and didn't come up with a solution that I felt was workable, especially with staff and no fiddling about.

I haven't bought one of the Exceed / WCW solutions, but probably will. Though I hate to spend the money when a cheap DIY solution may do a great job, i'm not convinced that we have found a suitable DIY answer.

I haven't bought one of the Exceed / WCW solutions, but probably will. Though I hate to spend the money when a cheap DIY solution may do a great job, i'm not convinced that we have found a suitable DIY answer.

RED Arrow - ends of pole sections than can get chipped

WHITE Arrow - If the hose pulls the fitting from being exactly plumb with the pole (which it will do) then the metal fitting will contacts the section ends as you are cleaning with the pole collapsed, and as you extend the pole.

You make the JG fitting a tight fit in the pole section, and so too for the male fitting in the JG......as 'Cheshire' mentioned earlier.......

1. Buy a pack of John Guest 22mm pipe inserts from B&Q - about £3 for 5 - Photo1

2. Slide out the No.1 section from a Gardiner (or most other brand poles) pole

3. Wrap tape around the stem of this fitting until it is a tight fit in the base of section 1 - Photo2 and 3

4. Slide a length of pole hose (either PU or PVC) through section 1 and exit through the new fitting at the base

5. Fit a Rectus male fitting to the base of the pole hose, ensuring that the clip is as close to the male fitting as possible - Photo 4 - Then push this tightly into the John Guest fitting as shown

6. At the top end of section 1 fit whichever gooseneck you want to use and then pull the pole hose as tight as possible out of the top of the gooseneck

7. Holding the pole hose tightly just above the gooseneck to stop it pulling back in, cut the pole hose above where you are holding it and push-fit on an 8mm-8mm straight connector with red locking clip already fitted to the pole hose

8. Let go of the pole hose and it will pull the 8mm-8mm fitting tight back against the gooseneck opening- Photo 5

9. Slide the No.1 section back down into the pole

10. Connect your brush to the gooseneck and then connect the Brush T to the gooseneck connector with a short length of hose - Photo 6

11. Remove the end cap from your pole and cut out a much larger hole with a sharp knife. There needs to be enough of a lip for the cap to stay in position on the base - Photo7 & 8

12. In use, connect the female coupling of the hose pack to the base of the pole, extend and use the pole - photo 9 & 9.1

13. When finished with the pole disconnect the female coupling by pulling back the collar and put the pole away

14. The complete kit of parts needed (most you should have already) - photo attached

This will take about 10 minutes at most to do.

W

WWC

Did that in one of my trials ages ago - too fiddly, especially if you have big hands.Or just use an 8mm jg hosetail on the reel hose and connect to pole hose with 8mm-8mm jg straight connector No damage gonna be caused with a plastic jg connector instead of the rectus one

mufcglen

Well-known member

- Messages

- 601

- Location

- Manchester

reading these posts above your really reading into it too much about scratching the internal walls, if you do it as i said with a push fit insert then either wrap the pole hose with tape and force it into the insert it will stay put and easy to push your rectus onto with one hand then dangling about, ive took a few pics of mine with a piece of 8mm reel hose glued into the pipe instead of tape as i found over time the tape came loose.

ive also attached pics of my reel hose side with the female rectus bare and with the exceed/wcw sleeve!

trust me it doesnt rub on the insides as the male is solidly stuck in the plastic insert!

View attachment 6199

View attachment 6196

View attachment 6197

View attachment 6198

ive also attached pics of my reel hose side with the female rectus bare and with the exceed/wcw sleeve!

trust me it doesnt rub on the insides as the male is solidly stuck in the plastic insert!

View attachment 6199

View attachment 6196

View attachment 6197

View attachment 6198

jimmyboots

Well-known member

- Messages

- 688

- Location

- Stoke on Trent

Hi Jimmy, but it does - sort of. The fitting is sitting out the bottom of pole 1. Yes the fitting stays stationary, but pole section 2 slides up and down the fitting every time you extend and collapse the pole. Which you do lots of times during the working day. The fitting has a loose water hose on one end and is bound to pull it down/sideways against the pole wall. Then you slide section 2 up and down on the metal.

This movement in the fitting will be even more exaggerated when using hot water, as the pole hose is even more flexible and likely to bend, allowing the metal fitting to rest on section 2.

The fitting may also knock agaist the sides as you brush - like an exterior hose can do against the outside of the pole if not well wrapped around the pole.

Also as I use more than 1 pole in the day, I can't leave it clipped in as you do. So, each time the metal fitting extends past the delicate ends of all the pole sections, it risks chipping the ends - especially section 2, when you extend after a full collapse. Or even if you are working with the pole fully collapsed e.g. the lower windows. The metal fittings will certainly rub against the pole ends then as you move the pole when working. I know that you JimmyBoots, keep your pole slightly extended all day, after you have carefully moved the fitting in past the pole ends - but staff won't. I'm not sure that I would remember either - too much muscle memory already in place.

RED Arrow - ends of pole sections than can get chipped

WHITE Arrow - If the hose pulls the fitting from being exactly plumb with the pole (which it will do) then the metal fitting will contacts the section ends as you are cleaning with the pole collapsed, and as you extend the pole.

All I can say is I have worked like this since November 2014 and havent had any problems, not even disconnecting, which I thought might have happened the odd time.

Heres a pic of my pole end taken from the Van just. I did put a little padding and tape round the fitting.

Similar threads

- Replies

- 9

- Views

- 974

- Replies

- 15

- Views

- 2,488

- Replies

- 10

- Views

- 1,031

- Replies

- 8

- Views

- 1,056

- Replies

- 25

- Views

- 2,631